Exact PipeCut AIR 360 Pneumatic Pipe Cutter – 7010411

9999 in stock

$0.00

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

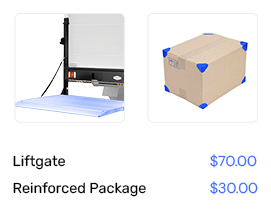

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

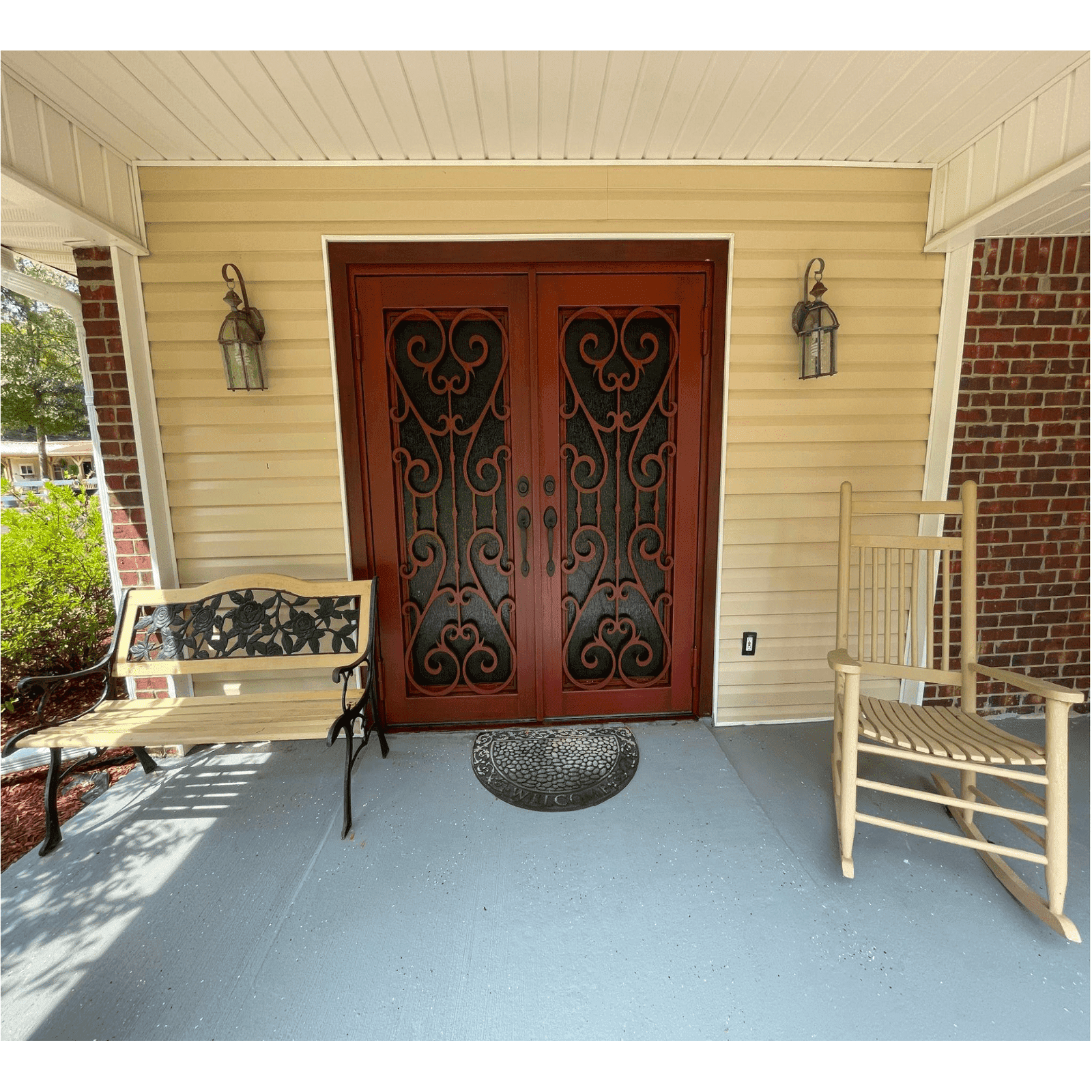

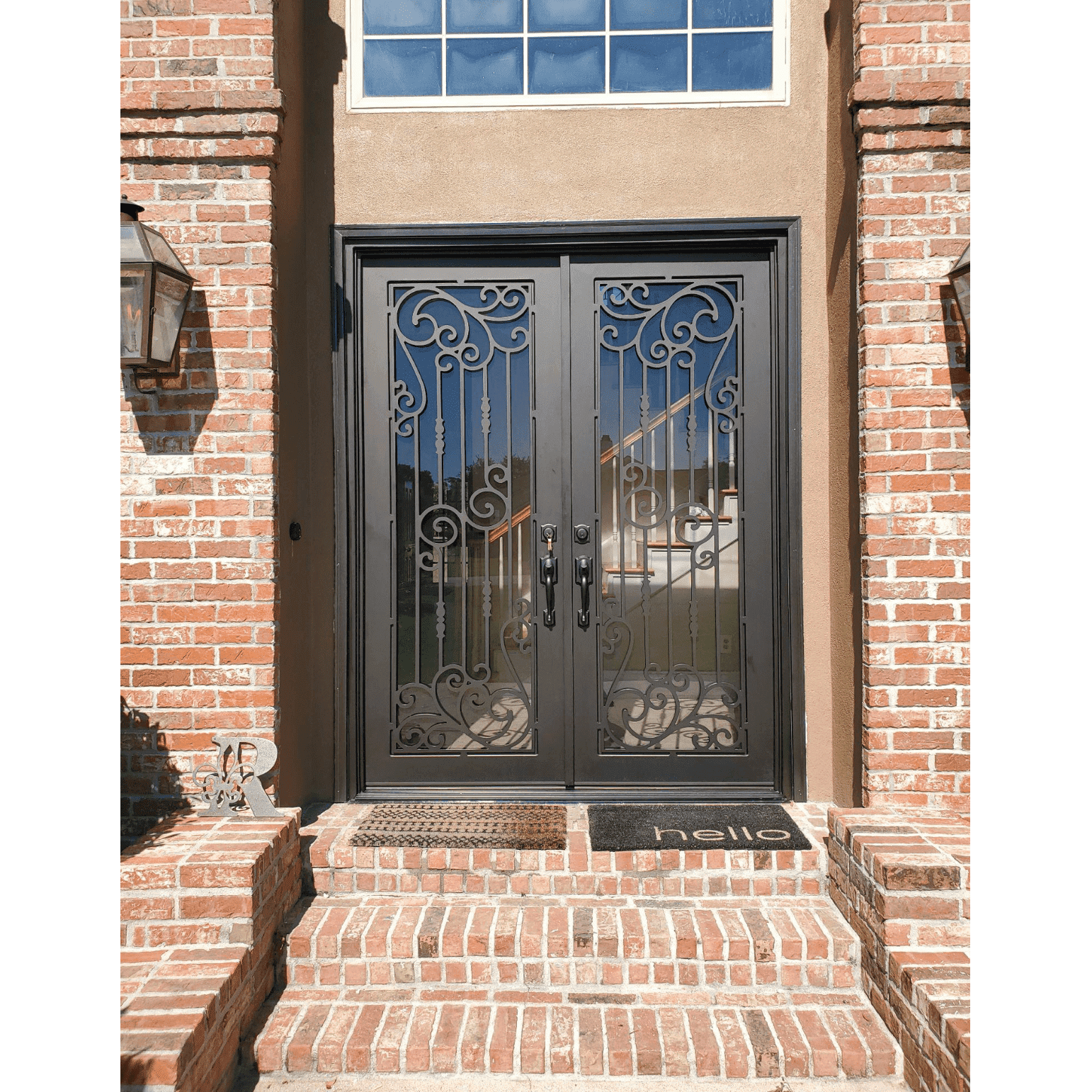

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Exact PipeCut AIR 360 Pneumatic Pipe Cutter – 7010411

Cut cement lined cast iron pipes for repair and maintenance applications. This pneumatically driven saw cuts cast iron, stainless steel, plastic, ductile nodular cast iron and aluminum pipes.

Features

- Cut steel, stainless steel, plastics, cast/ductile iron pipes

- Pneumatically driven

- Able to cut under water

Specifications

| SKU | 7010411 |

|---|---|

| Pipe Cutting Capacity | 4“ to 15“ (110mm – 360mm) |

| Max Wall Thickness | 1.8“ (45mm) Cast iron, 1.8“ (45mm) Plastic |

| Pipe Material | Aluminum, Cast iron, Ductile (nodular cast iron), Glass fiber, Plastic, Stainless/Inox steel, Steel |

| Power | 4.6 HP / 3.4 KW |

| Required Air Pressure | 6 bar / 90 psi |

| Blade Diameter | 180mm (7.09“) |

| Mounting Bore | 2.44” (62mm) |

| Weight | 59 lbs |

Includes

- PipeCut AIR 360

- Wrench with push stick

- A small funnel to fit into the oil inlet hole

- 5mm Allen Key for the oil port

Not included

- Air swivel connection

- Saw blade or diamond disc

- Air tool oil VGA 32

What our Experts Think

- Powerful Pneumatic Cutting – Ideal for hazardous or spark-sensitive environments.

- Fast & Precise – Delivers clean, accurate cuts on pipes up to 14″ in diameter.

- Heavy-Duty Build – Designed for industrial use with durable construction.

- Safe & Efficient – No sparks, heat, or dust—perfect for demanding job sites.

- Lightweight & Portable – Easy to transport and operate in tight spaces.

Q&A

Q: What is the Exact PipeCut AIR 360?

A: The Exact PipeCut AIR 360 is a high-performance pneumatic pipe cutter designed for fast, precise cutting of various pipe materials, including steel, plastic, and cast iron.

Q: What pipe sizes can it handle?

A: It is suitable for cutting pipes with diameters ranging from 3″ to 14″ (75mm to 360mm).

Q: What is the cutting method?

A: This cutter operates using a powerful pneumatic motor, providing spark-free, burr-free cuts with minimal effort.

Q: Is it suitable for hazardous environments?

A: Yes, its pneumatic operation makes it ideal for use in environments where electric tools are restricted due to safety concerns.

Q: What industries benefit from this tool?

A: It’s widely used in industries like oil and gas, water treatment, shipbuilding, and construction.

Q: Does it include a blade?

A: Yes, it comes with a high-quality cutting blade suitable for various materials.

Maintenance Tips

- Keep It Clean – Regularly remove dust and debris from the blade and motor housing.

- Lubricate Components – Apply pneumatic tool oil to moving parts for smooth operation.

- Check Air Supply – Ensure proper air pressure and moisture-free air for optimal performance.

- Inspect Blades – Replace dull or damaged blades to maintain cutting efficiency.

- Store Properly – Keep in a dry, dust-free area when not in use.

Additional information

| GoogleProductCategory | 2080 |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-30T08:03:24Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet