York International 3-6 Ton Power Exhaust Assembly 575 Volt, Phase:3 – 2PE04703058

9999 in stock

$660.00

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

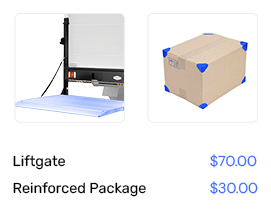

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

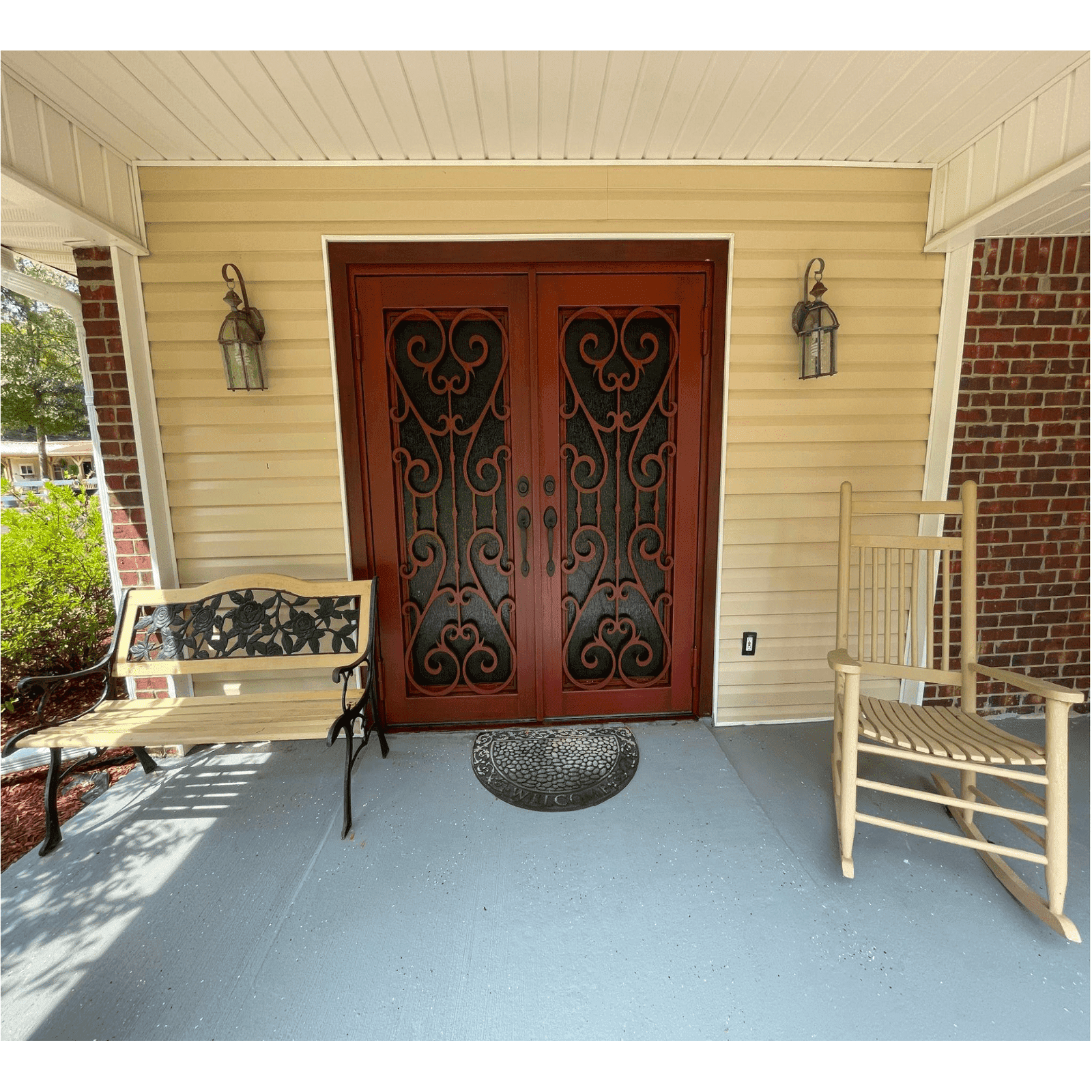

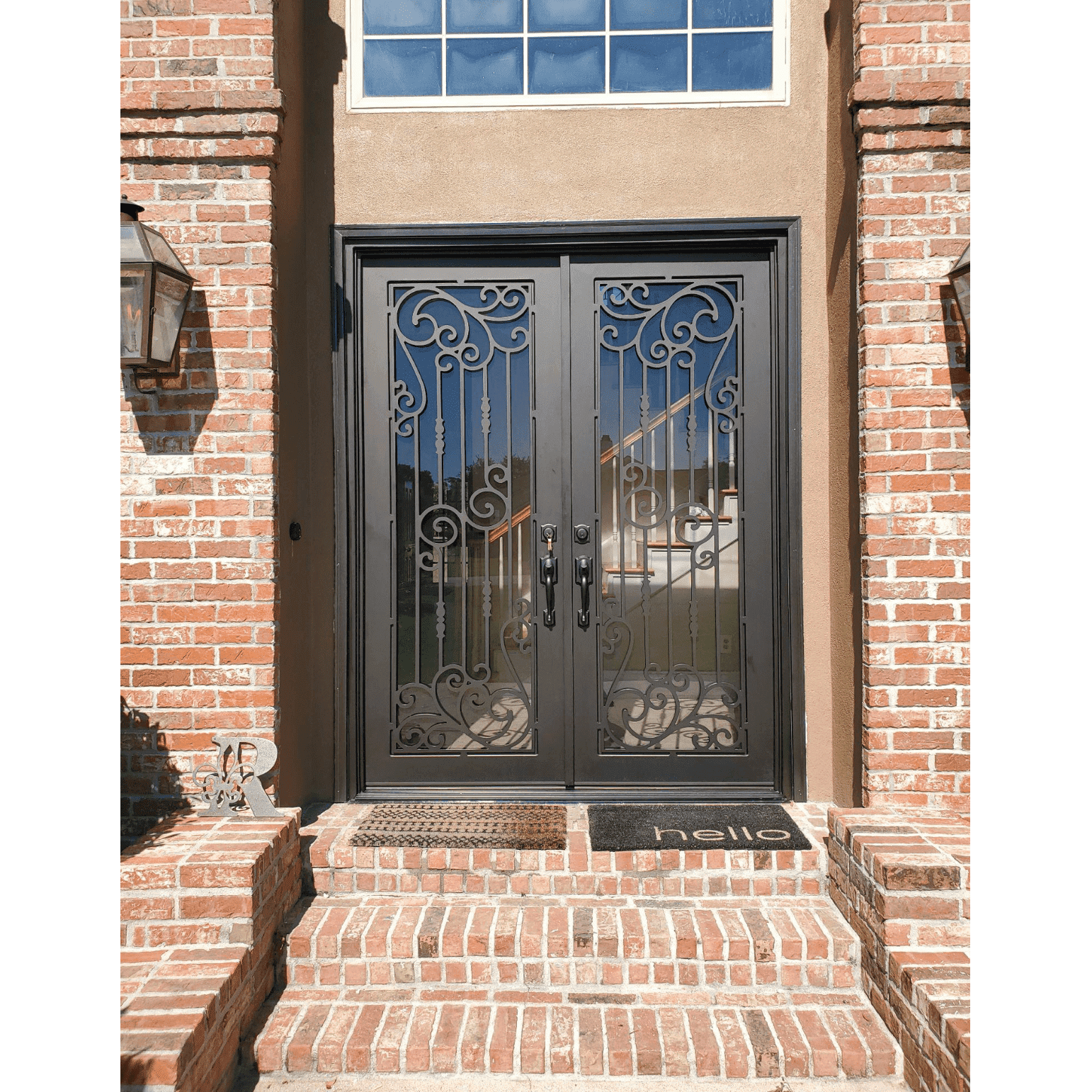

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

York International 3-6 Ton Power Exhaust Assembly 575 Volt, Phase:3 – 2PE04703058

Specification

| Cabinet Size: | 35 |

|---|---|

| Packaging: | Manufacture packaging |

What Our Experts Think

- Powerful Ventilation: The York International 3-6 Ton Power Exhaust Assembly is designed to provide strong and efficient ventilation for large systems, enhancing air circulation and maintaining optimal system performance.

- Durable and Robust: Built to handle heavy-duty use, this exhaust assembly is engineered with high-quality materials for long-lasting performance and reliability.

- High Voltage Compatibility: Operates at 575 volts and supports 3-phase power, making it suitable for commercial and industrial applications that require robust exhaust solutions.

- Efficient Airflow: Designed to handle substantial airflow, it ensures proper venting of air, reducing system strain and improving efficiency.

- Versatile Application: Ideal for use in large HVAC systems, warehouses, and industrial settings where high-powered ventilation is required.

Q&A

Q: What is the York International 3-6 Ton Power Exhaust Assembly used for?

A: This assembly is designed to provide ventilation and air circulation for HVAC systems in commercial or industrial applications, accommodating units with capacities ranging from 3 to 6 tons.

Q: What are the key features of the York International Power Exhaust Assembly?

A: It operates at 575 volts, three-phase power, and is engineered for compatibility with 3-6 ton HVAC systems. The assembly enhances airflow and exhaust performance, ensuring optimal system efficiency.

Q: What applications is this power exhaust assembly suitable for?

A: It is ideal for commercial and industrial settings where robust ventilation is required to maintain air quality and regulate pressure within the HVAC system.

Q: Why choose the York International 3-6 Ton Power Exhaust Assembly?

A: This unit delivers reliable performance, supports efficient system operation, and is specifically designed to complement York HVAC systems in demanding environments.

Maintenance Tips

- Inspect and Clean Regularly: Check for dirt, debris, and blockages in the exhaust assembly and clean as needed to maintain airflow efficiency.

- Lubricate Moving Parts: Lubricate motors and bearings periodically to reduce wear and ensure smooth operation.

- Inspect Electrical Connections: Ensure all wiring and connections are secure and free from damage or corrosion.

- Check Motor Functionality: Test the motor to ensure it operates correctly and replace any worn or faulty components promptly.

- Verify Voltage and Phase Compatibility: Regularly confirm the unit operates within the specified voltage (575V) and phase (3-phase) parameters.

- Inspect for Wear: Monitor the assembly for signs of wear, such as rust or fatigue in the housing, and address issues promptly.

- Schedule Professional Servicing: Have the assembly inspected by a professional annually to maintain optimal performance and safety compliance.

Additional information

| Weight | 65 kg |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-06-05T16:41:19Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Sale 40%

York International 2 Ton “Affinity” Series Two-Stage Split-System Air Conditioner/W ECM Fan Motor, 18 SEER 208-230/60/1 – CZH02412CA

$1,505.00Original price was: $1,505.00.$899.00Current price is: $899.00. -

York International 30,000 Btu Mulit-Zone OD Mini-Split Heat Pump/W Mod Inverter, 16 Seer 208-230/60/1 R-410A – DHMF30CMM42Q1A

$819.00 -

York International 4 Ton “LX” Series Split-System Air Conditioner, 13 SEER 208-230/60/1 R-410A – YCD48B21SA

$1,049.00 -

York International 24 Kw Electric Heat Kit W/ Circuit Breakers; 208/240/60/3 – 2TP04512325

$749.00

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet